Bass Traps

Bass Traps

Acoustic Panels

Acoustic Panels

Bass Traps

Bass Traps

Acoustic Panels

Why Do We Need Bass Traps?

Bass traps are designed to absorb excess low-frequency sound reflections, which tend to linger in spaces due to their long wavelengths relative to the room’s size. Unlike higher frequencies that are easier to control with thinner acoustic panels, low frequencies are more prone to creating resonances like standing waves and room modes—which result in uneven frequency response and decay times in your space.

Without bass traps, you risk overemphasizing certain frequencies while underrepresenting others, creating an imbalanced listening environment. In addition, the longer decay times at some bass frequencies can audibly resonate, and are often more indicative of what the room sounds like than the frequency imbalances.

Where Should You Place Bass Traps?

The best starting point for placing bass traps is typically in the corners of the room, where low-frequency sound waves tend to converge and build up the most. This is why corner traps are highly effective at capturing and absorbing these frequencies.

Regardless of the room dimensions, bass buildup occurs along flat walls and the ceiling as well - especially in smaller spaces like home studios or control rooms. That is why we want to install deeper panels along the walls to further smooth out the frequency response and reduce resonances. But keep in mind: overall performance is more about coverage area (how many square feet of bass trapping are we adding?) than anything else.

Choosing the Right Bass Trap for Your Space

Selecting the right treatment depends on the size and acoustical needs of your room. Here are the different types of bass traps we offer:

Material Matters:

Why Studiofoam Isn’t Enough

Material choice plays a critical role in the effectiveness of low-frequency absorption. Many inexpensive treatment options on the market are made from acoustic foam, which is often marketed as a one-size-fits-all solution for sound treatment. However, acoustic foam is less effective at absorbing low-frequency sound compared to larger and more robust materials like mineral wool and fiberglass.

Acoustic Foam vs. Mineral Wool

Acoustic foam can be effective for absorbing high frequencies, but it falls short when it comes to managing low-end sound energy. Its gas flow-resistance properties generally do not allow low-frequency sound waves to fully enter the material to be absorbed. On the other hand, mineral wool and fiberglass are more optimized across various thicknesses for more efficient absorption of low frequencies. This makes them the preferred materials for effective bass traps.

Thicker is Better

Thickness matters, all else being equal. A deeper trap will be more effective at the deeper bass frequencies, because the sound waves have to travel farther within the material. At GIK Acoustics, our bass traps range from 4” to 10” thick, ensuring they absorb the broad range of low-frequency sound that can distort your listening environment.

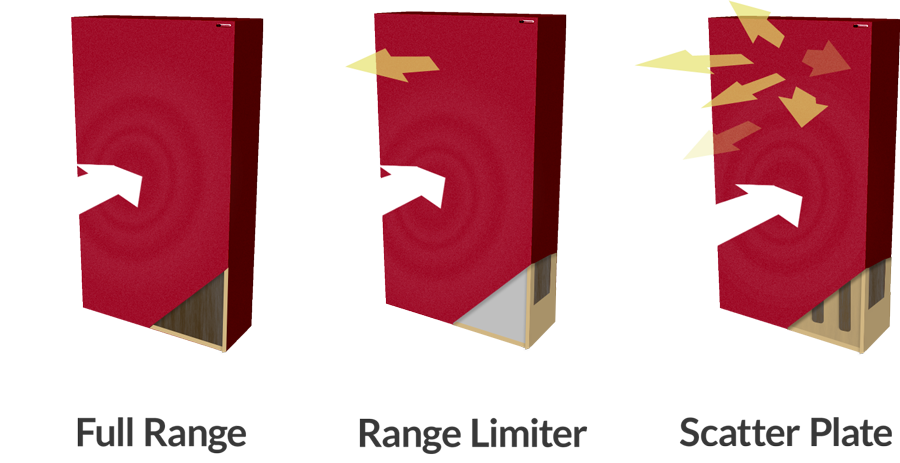

Our patented FlexRange technology also incorporate a built-in air gap for even better performance, and the frequency response of the device can also be contoured as needed with Range Limiters to maximize bass absorption, and reduce midrange/treble absorption for a more balanced room that isn’t too dead.

For more information read this article:

https://www.gikacoustics.com/how-bass-traps-work/

High-Quality Materials and Craftsmanship

GIK Acoustics is known for using only the highest-quality materials in our products. Unlike many products on the market that use cheap or inefficient materials, we prioritize performance and durability in every product we make.

Fiberglass and

Mineral Wool

Our products use fiberglass and/or mineral wool as their absorption core, which provides excellent broadband absorption across the entire frequency range, particularly for low frequencies with thicker panels. These materials are far more effective than generic acoustic foam at controlling low-frequency sound.

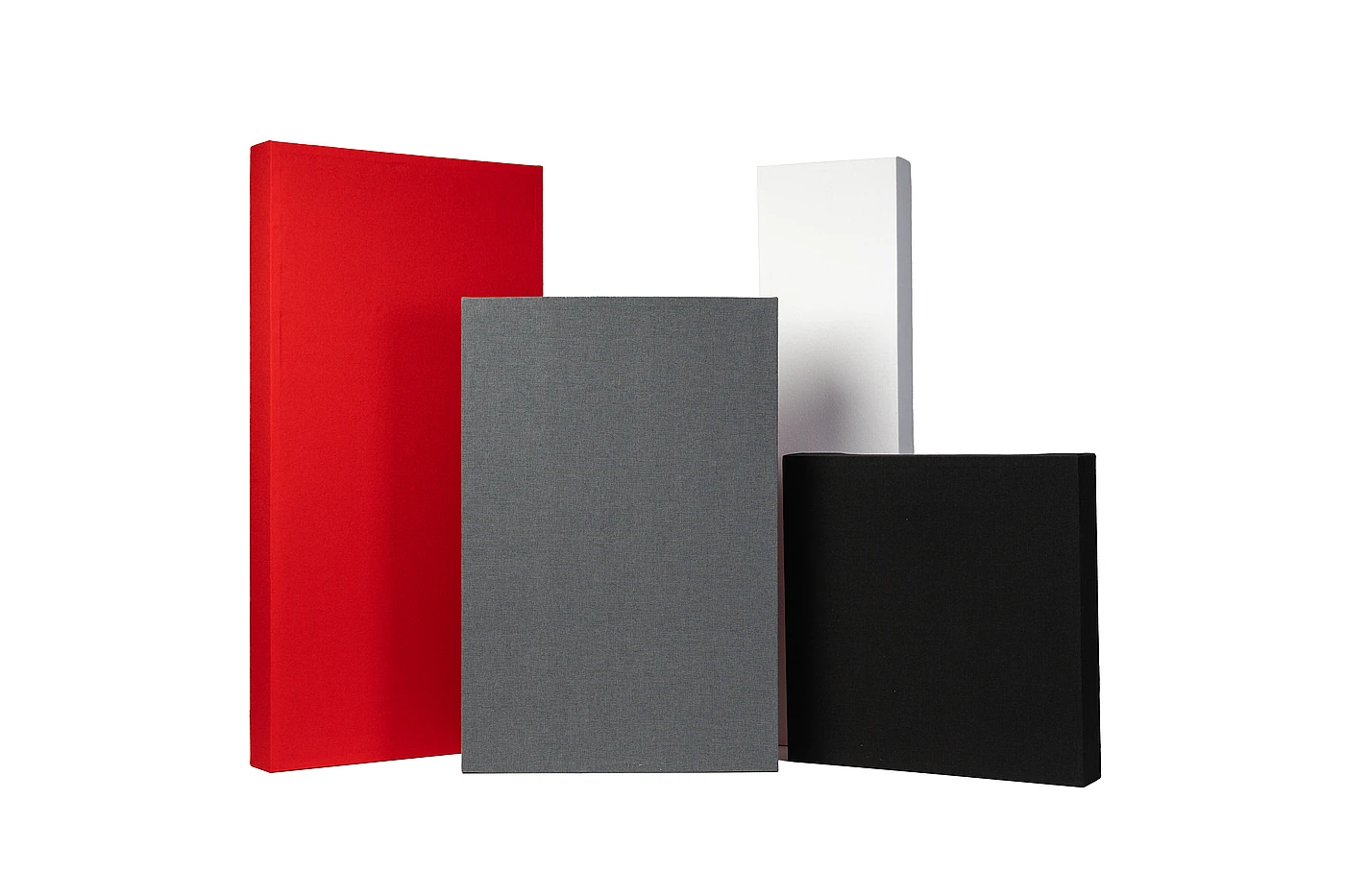

Guilford of Maine

Acoustic Fabrics

We offer a range of beautiful, durable fabrics, including the full line of Guilford of Maine products. These high-quality acoustic fabrics ensure that your treatment not only performs well but also complement the aesthetic of your room.

Custom Sizes

and Designs

Every space is different, which is why we offer custom sizes and design options for many of our products. Whether you need a specific size for a trap corner or a freestanding unit for an irregular room, we can provide a tailored solution.

Achieve Superior Sound Control with GIK Acoustics Bass Traps

If you’re looking to create a balanced, distortion-free listening environment, bass traps are a critical part of your acoustic treatment strategy. Whether you’re setting up a home studio, enhancing a home theater, or perfecting the acoustics in your recording studio, GIK Acoustics provides the highest-quality bass traps to manage low-frequency sound and improve overall sound quality.

Contact us today for Free Acoustic Advice and explore how our custom panels, corner bass traps, and freestanding units can transform your space into a high-end listening environment.

Frequently Asked Questions (FAQ)

Do I Need Bass Traps?

All rooms will benefit from a bass trapping strategy. If you have issues with low-end distortion, bass resonances, or standing waves, you will notice an immediate improvement once the bass traps are installed. They are essential for anyone looking to improve the clarity and accuracy of low-frequency sound in their space.

Where Should I Put a Bass Trap?

Bass traps help literally everywhere you can put them in a room! But the most effective placement is typically in the corners of the room, where bass frequencies tend to accumulate. You can also place them along walls, especially if your room has irregular dimensions that cause uneven frequency response.

How Do I Decide Which Type of Bass Trap to Purchase?

Choosing the right bass trap depends on your room’s size and shape, as well as the level of bass absorption you need. Corner bass traps are ideal for most rooms, but wall panels or freestanding units may be more suitable for larger or unusually shaped spaces. One key question is, how much space inside the room is available to improve the low end?

What Material is Best for My Space?

Fiberglass and mineral wool (like Owens Corning or Knauf) are the best materials for bass treatment because they offer excellent broadband absorption, particularly in the low-frequency range. Unlike acoustic foam, these materials are more optimized for maximum low frequency performance.

Do You Offer Design Services?

Yes, at GIK Acoustics, we provide Free Acoustic Advice to help you choose the best treatment strategy for your space. Our experts can guide you on the best placement and combination of products to achieve optimal sound quality.